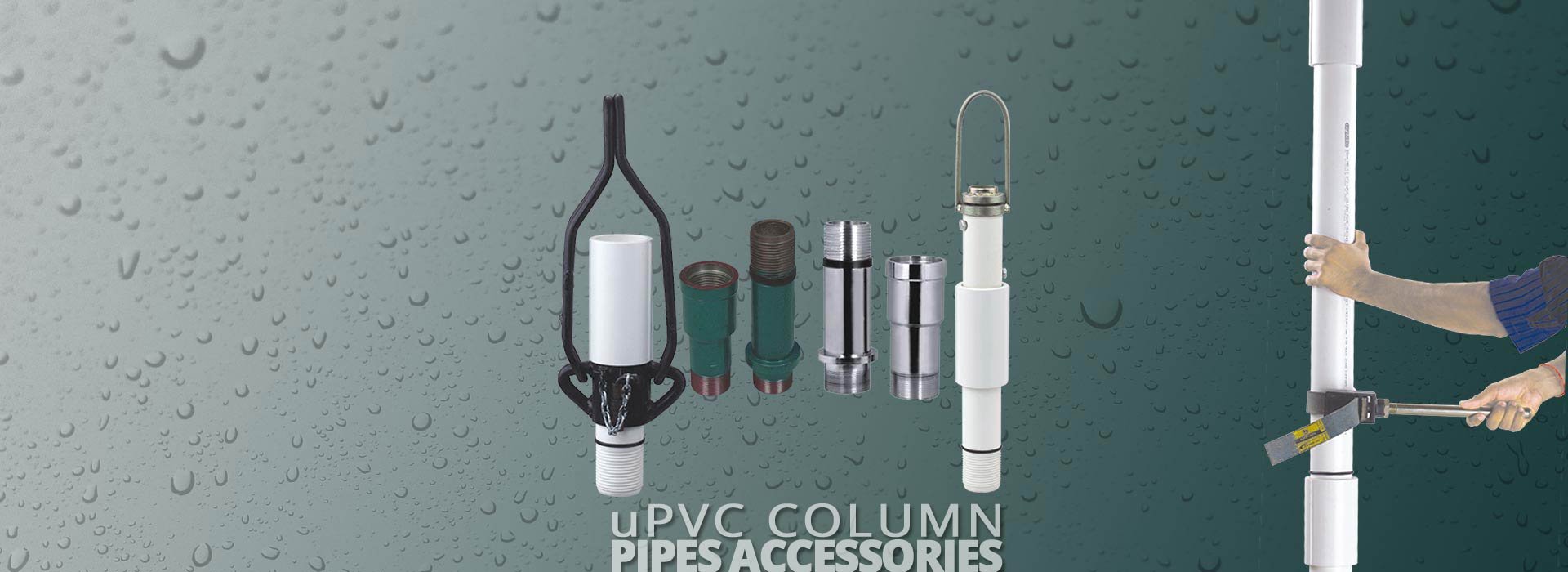

uPVC Column Pipes Accessories

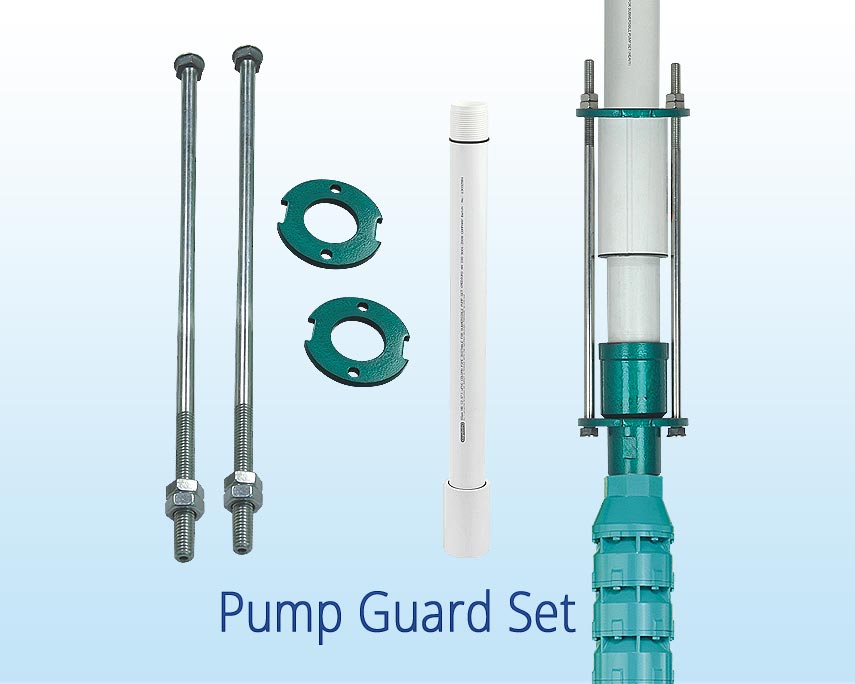

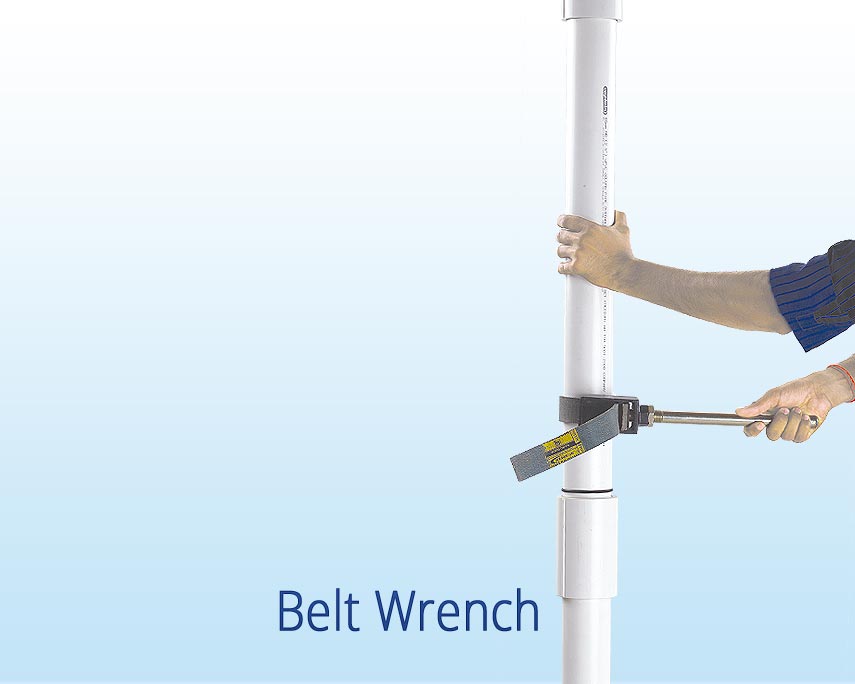

CAPTAIN offers best quality uPVC Column Pipe Accessories which includes Adaptor Set, Pump Guard Set, Belt Wrench, Sigri, etc. We recommed using genuine Captain accessories with our uPVC column pipes | uPVC Borehole pipes to assure the best result.

PRODUCT RANGE

- uPVC Column Pipes | Borehole Pipes

- uPVC Column Pipe Accessories

- uPVC Pressure Pipes

- uPVC Pressure Pipes Fittings

- uPVC Plumbing Pipes & Fittings

- CPVC Plumbing Pipes & Fittings

- SWR Pipes & Fittings

- uPVC Casing Pipes

- uPVC / PVC / CPVC Solvent Cement

- Garden Hose Pipes

- Suction Pipes

- HDPE Pipes

- Irrigation Equipments